https://jackpotchips.com/machine-shop-near-me/ Precision crafting of tools and parts for your needs with CNC machine shops.

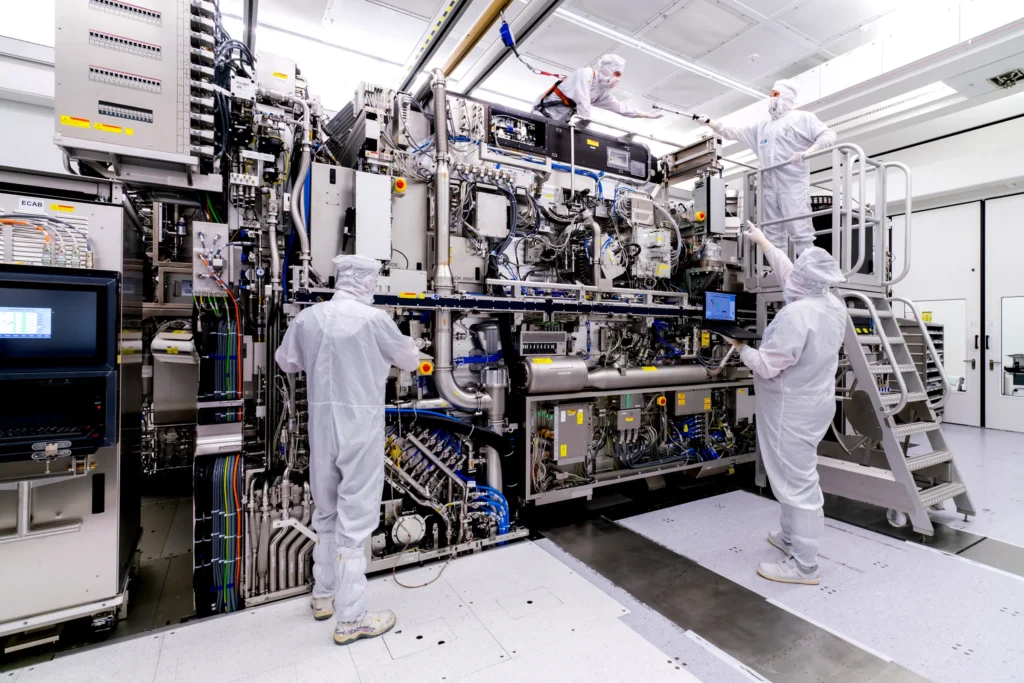

When first walking into one of any of the CNC machine shops around the country, you may ask yourself exactly what you need to know about what goes on in these shops and a little about the process. The basic explanation of what happens in a precision machine shop is quite simple. It is an assembly line process, in which numerical commands are fed into a machine, which translates those commands into robotic actions, resulting in the creation of an object or objects from a solid block of raw metal.

These numerical machines can be used to create any number of useful, everyday objects. something as simple as a set of nuts and bolts for use in a larger project, or a set of perfect precision parts for a small machine, or as complex as the components for medical equipment, or aerospace gear, ground down to a perfect shape, ready to fit with the larger machine as a whole.

When ordering a precision part, make sure you know exactly what it is you want this unit to do. The operators will need the exact size and shape specifications of the object or objects you need made, so that they can convert those measurements into a numerical code and feed it into the machine. Being specific with your needs allows the operators to deliver the best possible service they can.

The great thing about units made in a precision machine shop is that these objects are perfectly uniform, sturdy, and ready and easy to sell to an end-user in search of an excellently made part or piece. They are also ready quickly, with a small unit taking as little as a half an hour to complete, and larger units taking only a day at the most.

CNC machine shops are exactly what are needed for any precision-made product or tool you or your business might need.

Three Factors to Consider Before You Set Up Your Home Machine Shop

The first and foremost factor to consider when starting your home machine shop is whether or not this will be for business or pleasure. If you just like to tinker and enjoy fixing things yourself, you can get by with much smaller, more versatile machinery than if you are going to accept outside work. There are three basic machine tools that perform the bulk of the jobs that you will encounter, the drill press, the milling machine, and the lathe. The home hobbyist can usually get by with a multi-purpose machine that incorporates all three of these into one versatile machine, but the serious machinist will want to set up shop with individual machines. You may already have a small drill press mounted on your work bench as it is a very useful and necessary machine.

The next item to consider is floor space. You can buy bench top drill presses, bench top mills, and bench top lathes at very reasonable prices, so even the home hobbyist might want to consider this avenue rather than the multi-machine. This allows much greater versatility and will help to eliminate the set-ups and tear-downs that you will likely encounter if you only have the multi-machine. There is nothing more frustrating than having to tear down a milling job just to drill a hole in order to make a special clamp for that same milling job. For the home machine shop, you will need to acquire much larger equipment. You may be able to get away with one of the larger bench top mills when starting out, but I would highly recommend that you buy a large drill press with a #4 Morse taper spindle and as low an RPM as you can find.